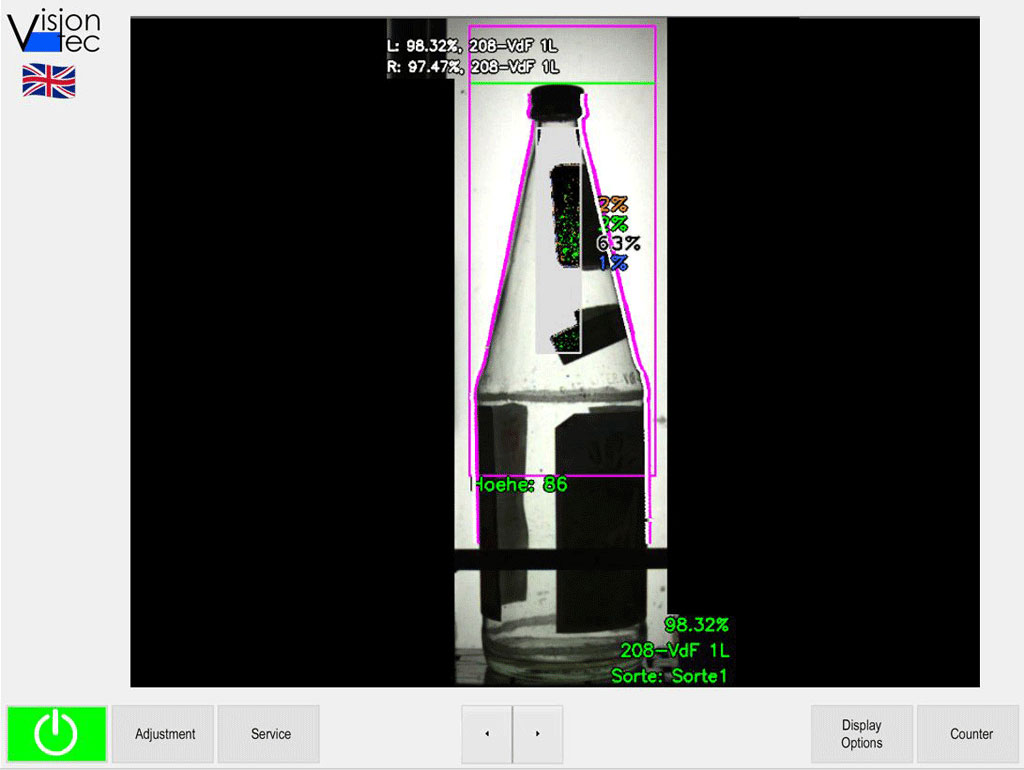

Single bottle sorting

The identification of individual bottles on the conveyor belt is mainly necessary prior to filling in order to detect and subsequently eject bottles that cannot be processed – thus ensuring productivity.

The individual bottle detection is used in sorting to distinguish bottles of different contours and colours from each other.

To identify the individual bottles on the conveyor belt, the following criteria are checked, depending on the task:

- bottle contour

- bottle colour

- bottle height

- Differentiation between white glass bottles with and without ultraviolet coating

- UV markings on the label

- Branding (Relief)

- ACL label

- Presence of the closure

- Horizontal bottles

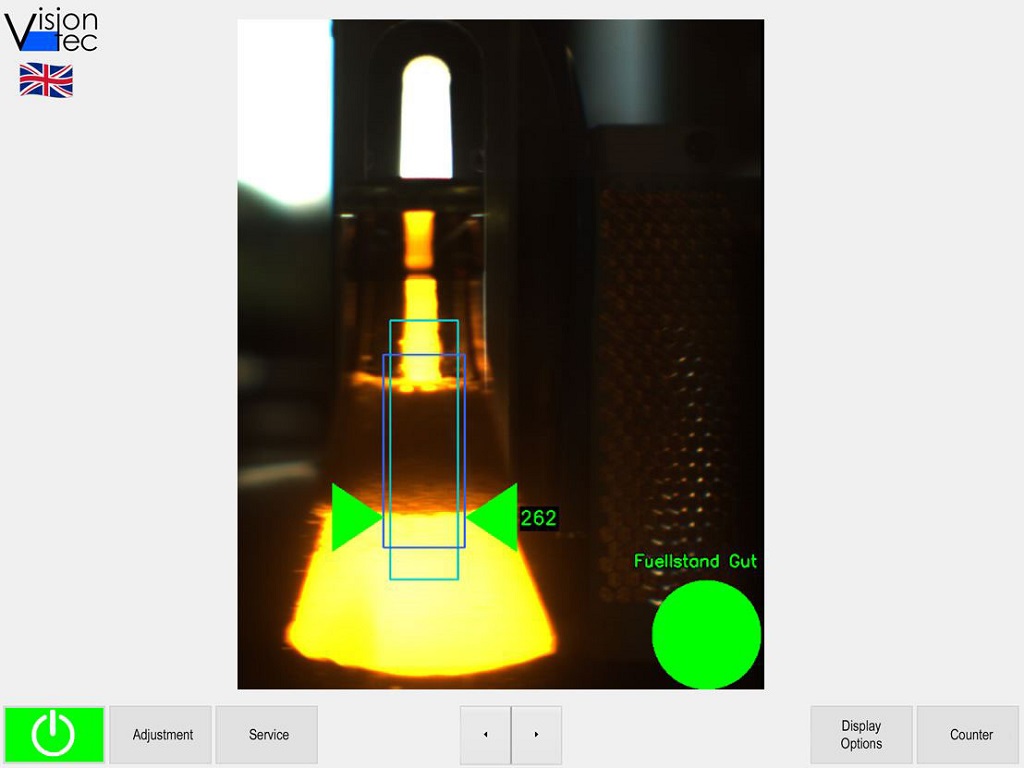

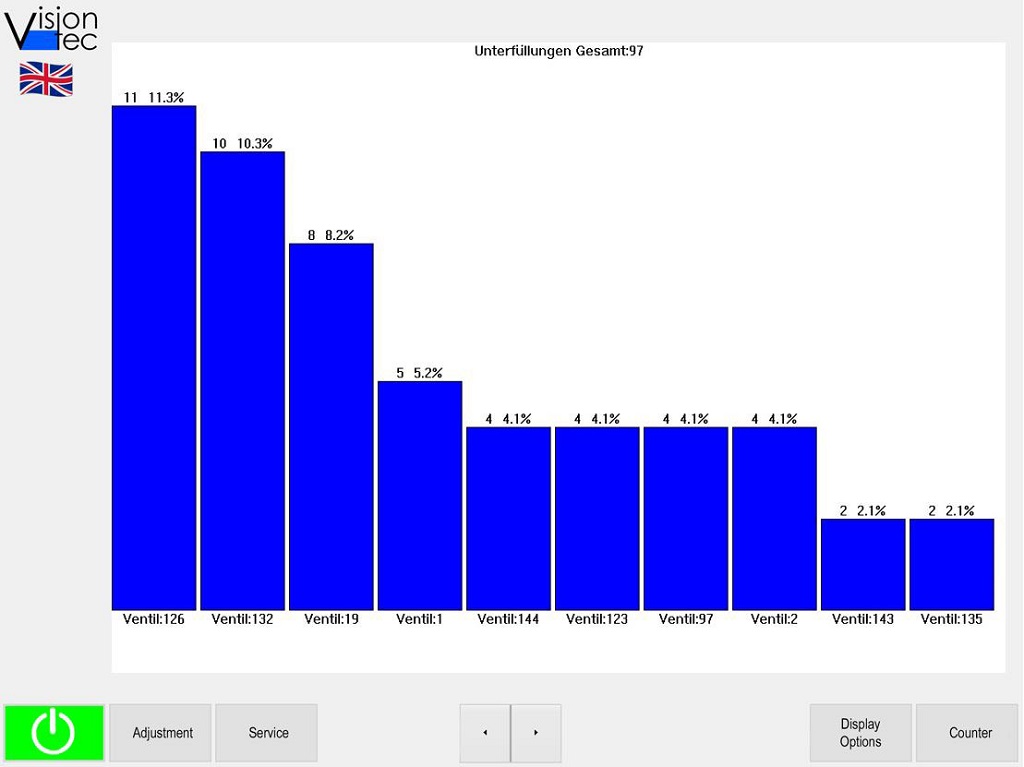

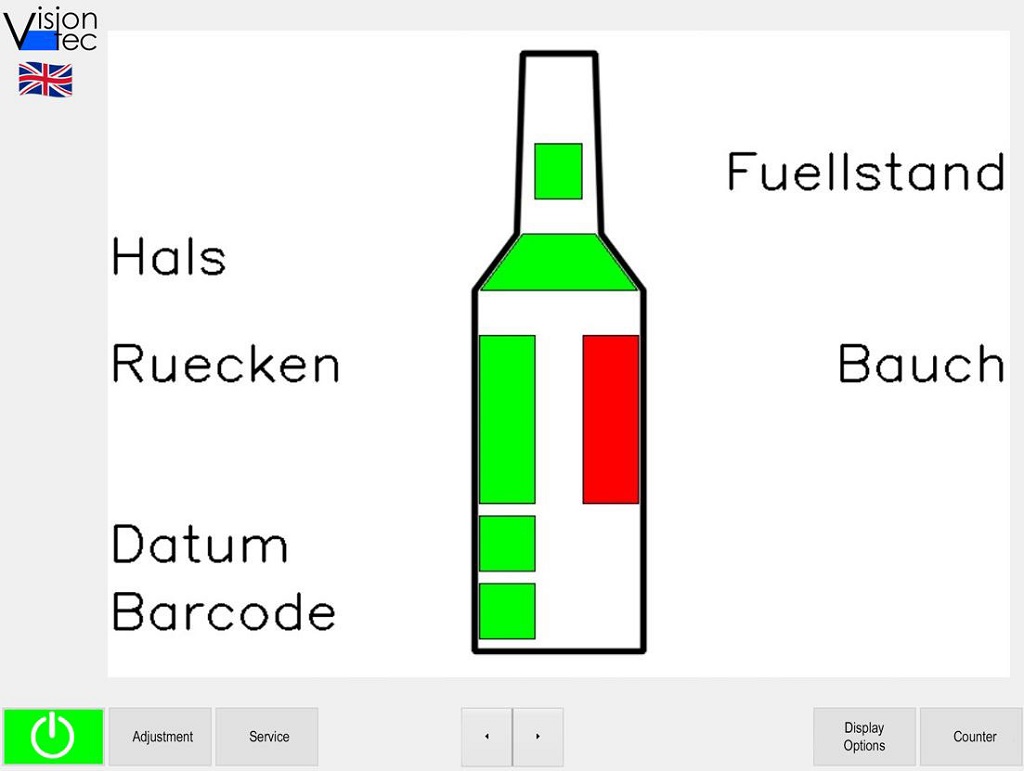

Fill level inspection

During the fill level inspection by means of a camera system, a triggered image of each bottle is recorded and evaluated. The level control works in transmitted light mode in order to create an easily evaluable image for all beverage variations. The fill level is determined by measuring the fill level foam limit to the cap from top to bottom.

The HF level inspection system is used for bottles that cannot be X-rayed (e.g. painted bottles or clay bottles). The system consists of two temperature-compensated measuring heads, which are encapsulated in V2A housings and thus have protection class IP67. The two measuring heads together form a measuring bridge. The design of the measuring bridge compensates for foam so that the foam is included in the level calculation. An additional foam sensor is mounted for reliable detection of foamed bottles. In addition, the system can be equipped with an inductive sensor to check the presence of the closures.

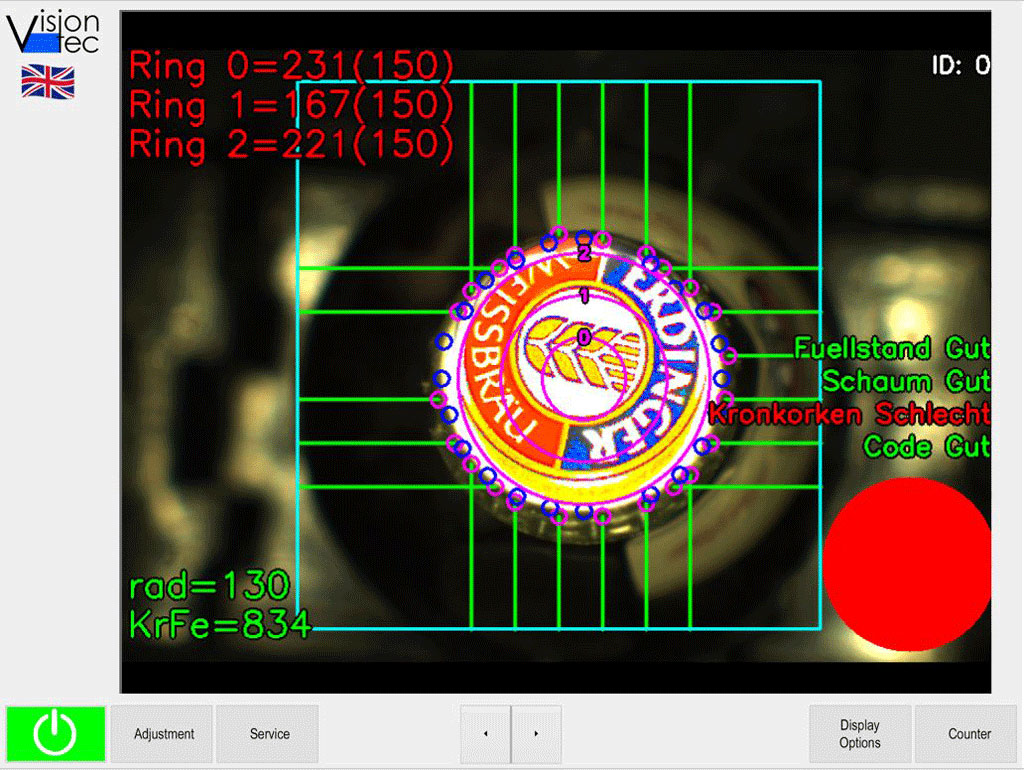

Cap inspections

The crown cork inspection works with a camera system to check the integrity of the outer sealing area of the crown cork by means of an optical gradient measurement. Due to the special design of the illumination device, the outer round area of the crown cork is illuminated in such a way that a homogeneous circular ring is created in the camera image, from which both the width and the roundness and homogeneity are evaluated. Furthermore, the imprint of the crown cork is evaluated. The image evaluation of the rotationally invariant logo image is carried out using the comparison with the taught-in sample images.

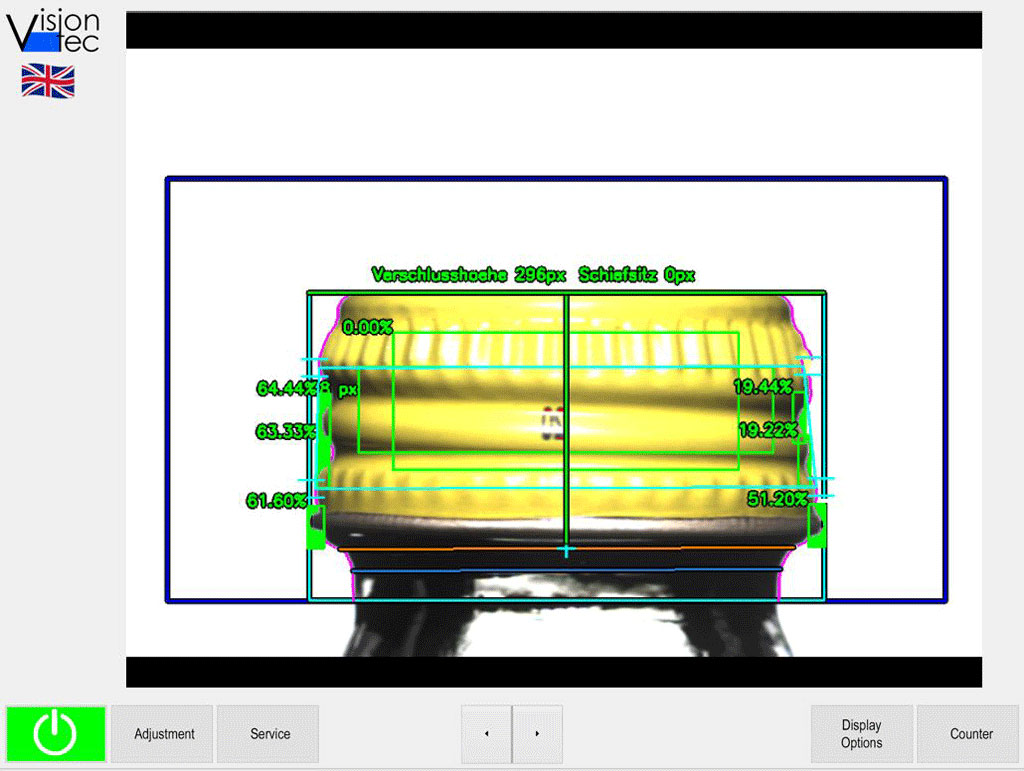

The 360° quality inspection checks the presence, the seat and the integrity of the closure as well as (in the case of screw caps) the seat and the completeness of the retaining ring.

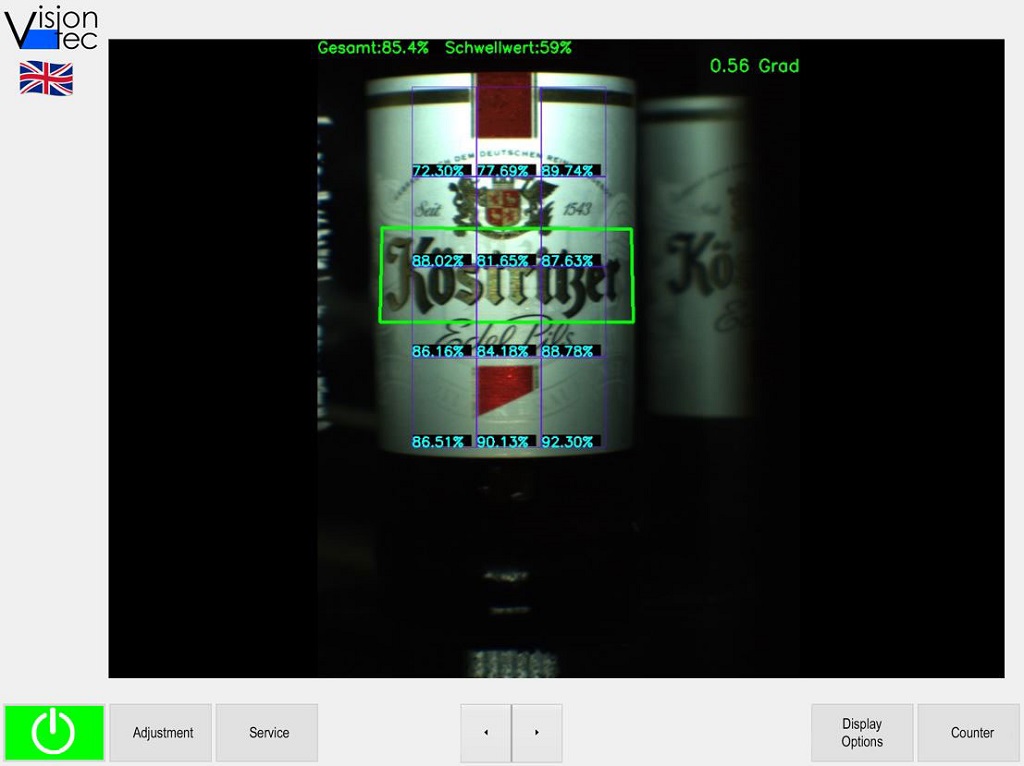

Label inspections

The label inspection system, which is equipped with one or more camera systems depending on the task, checks the following inspection criteria:

- Presence of the label

- Position of the label

- Rotational position of the label

- Label category accuracy

- Label offset

- Bar code

- Date imprint

If only the presence of the labels is to be checked, a simple inspection using light scanners is often sufficient. For each label position (e.g. body, back, neck, medallion), an alternator sensor is installed in the labeller immediately after application/brushing. The presence of the closure is inspected with an additional light sensor in the infeed of the labeller.

Print character inspections

The print character inspection to check the barcode and/or the best before date checks – depending on the task – the following inspection criteria:

- Presence of date imprint/barcode

- Completeness of the imprint

- Readability of the imprint

- Correctness of the content of the imprint („OCR”)

Also in the product portfolio

- Fill tube detection

- Ultrasonic bath

- Vacuum inspection

- Leach inspection

- Residual liquid inspection

- Swing-Top bottle inspection

You have questions about our products?

I’m here for you.

Thorsten Weinmann

Project and Sales Manager

E-Mail: t.weinmann@vision-tec.de

Tel.: +49 (0)561 979800-11