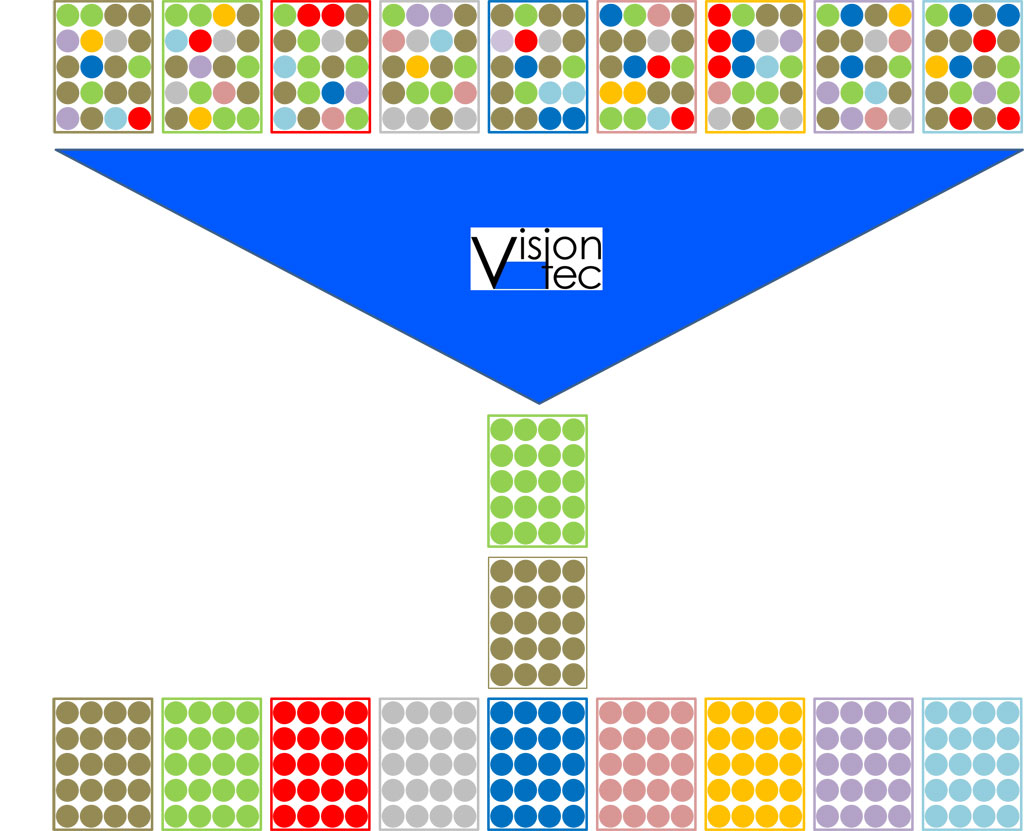

Effective sorting of the main types by direct exchange.

The problems are well-known, especially to our customers with several production types and those who collect additional bottle types for exchange with their market companions. These are staff shortages, increasing variety of types and limited availability of empty crates. The latter, in both manual and automatic sorting, often leads to the fact that although the right bottles are packed into the right crates, this generates many empty crates that have to be collected again before they can be filled with the right bottles.

With our innovative “green” sorting concept, in which up to 10 bottle types are sorted simultaneously, this so-called “empty crate tourism” is now avoided.

There is one infeed lane for each crate/bottle type to be sorted.

The next crate to be sorted is selected on a “target crate basis”. The robot only requests a crate when it has enough suitable bottles for it in the buffer – regardless of which bottles are currently still in the crate. In this way, the bottles in the crate are exchanged directly – without the diversions via separately supplied empty crates.

The green sorting concept, your logistical energy passport for the sorting plant!

- Saving of work steps

- Staff savings

- Energy saving