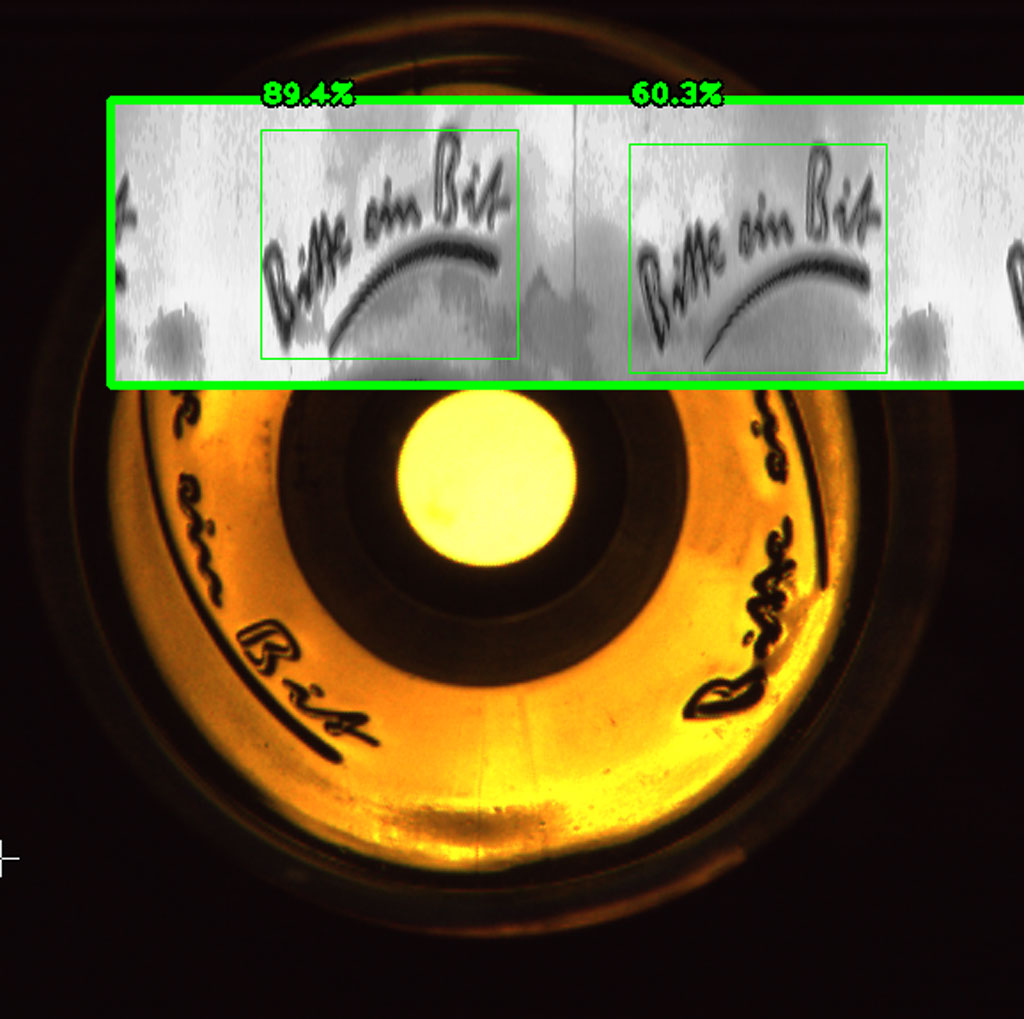

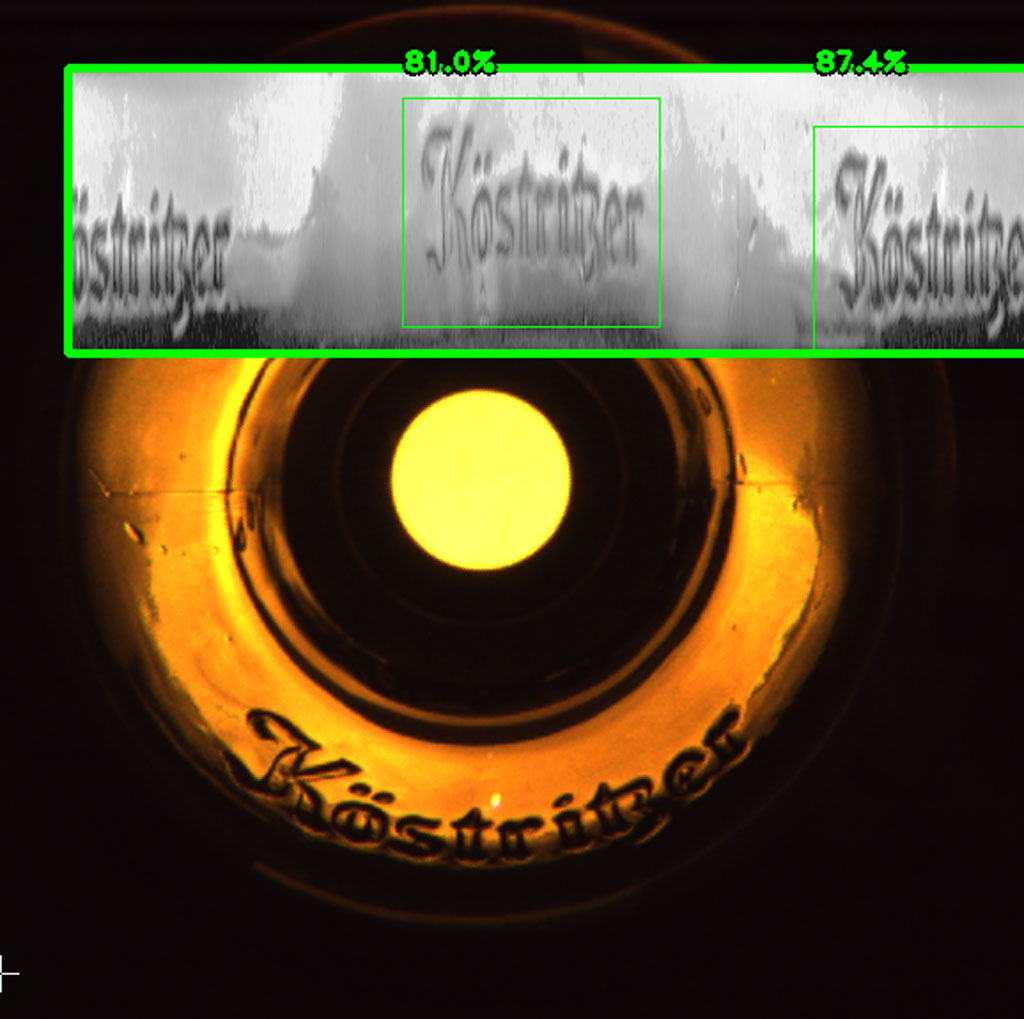

Individual bottles

Example video (Sternquell Brewery Plauen):

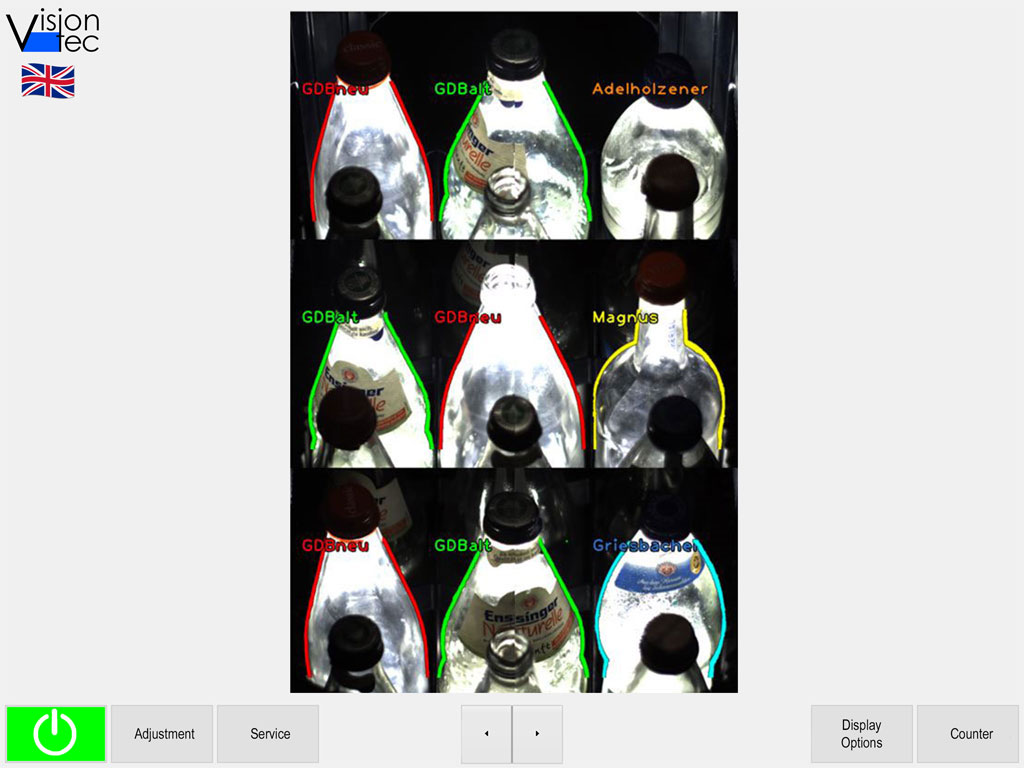

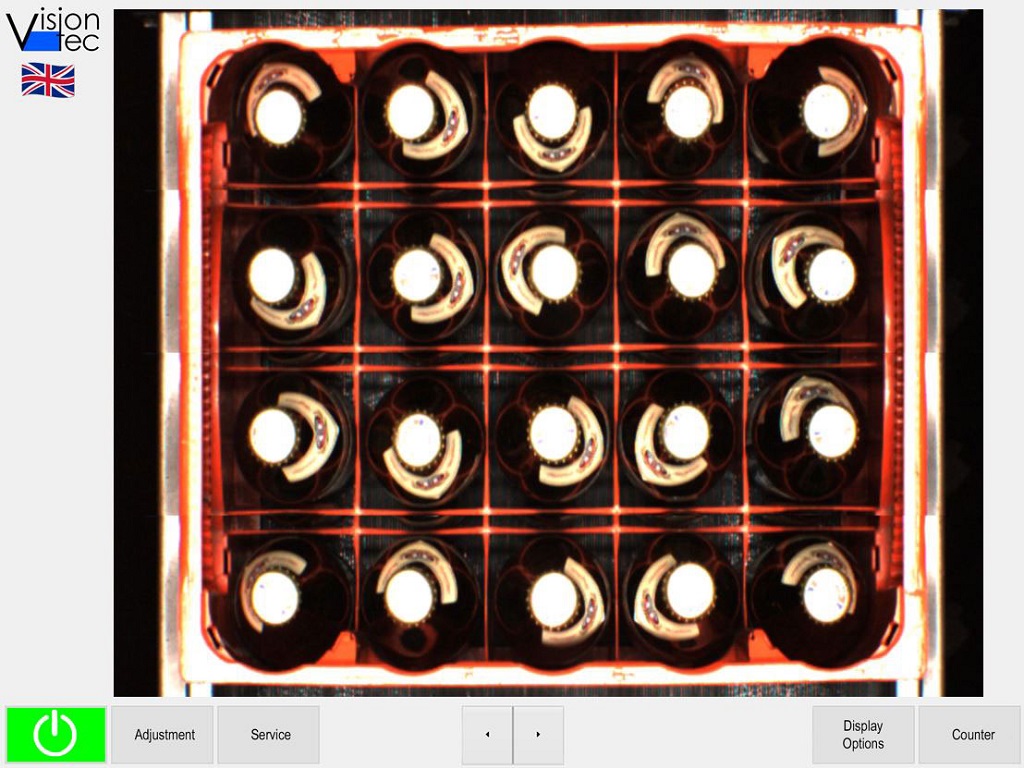

Deposit value inspections

The empties inspection system, specially developed for industrial deposit value recording, is mainly used by retail stores, the beverage trade, breweries and mineral bottlers, where the returned empties are credited to suppliers or customers. While the crates with an output of up to 4,000 c/h run through the inspection, more than 1,200 crate types with more than 90 bottle types are detected and inspected.

Advantages:

- Exact deposit value determination for exact credit note creation

- Control of the supplying retailers, intermediaries, innkeepers and/or branches

- Complete traceability with securing of evidence images

- Current and complete overview of the actual stock level

- Use of the vision-tec database with more than 1,200 existing crate types

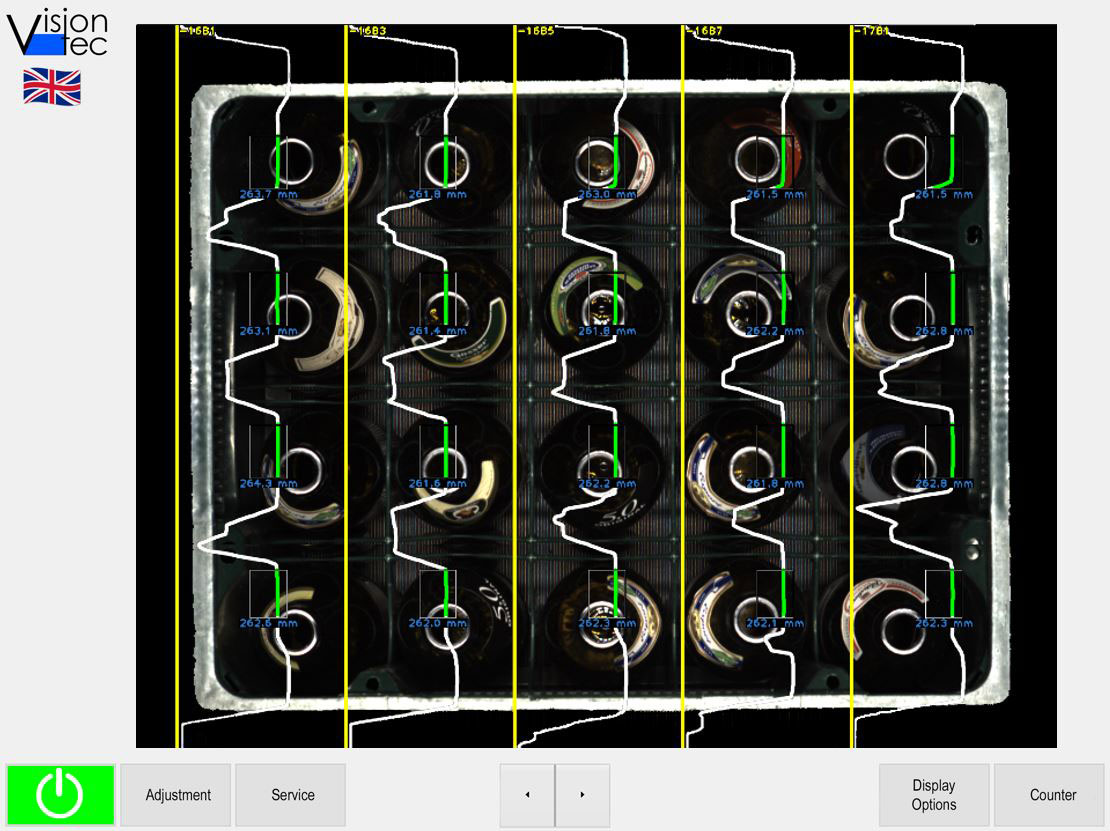

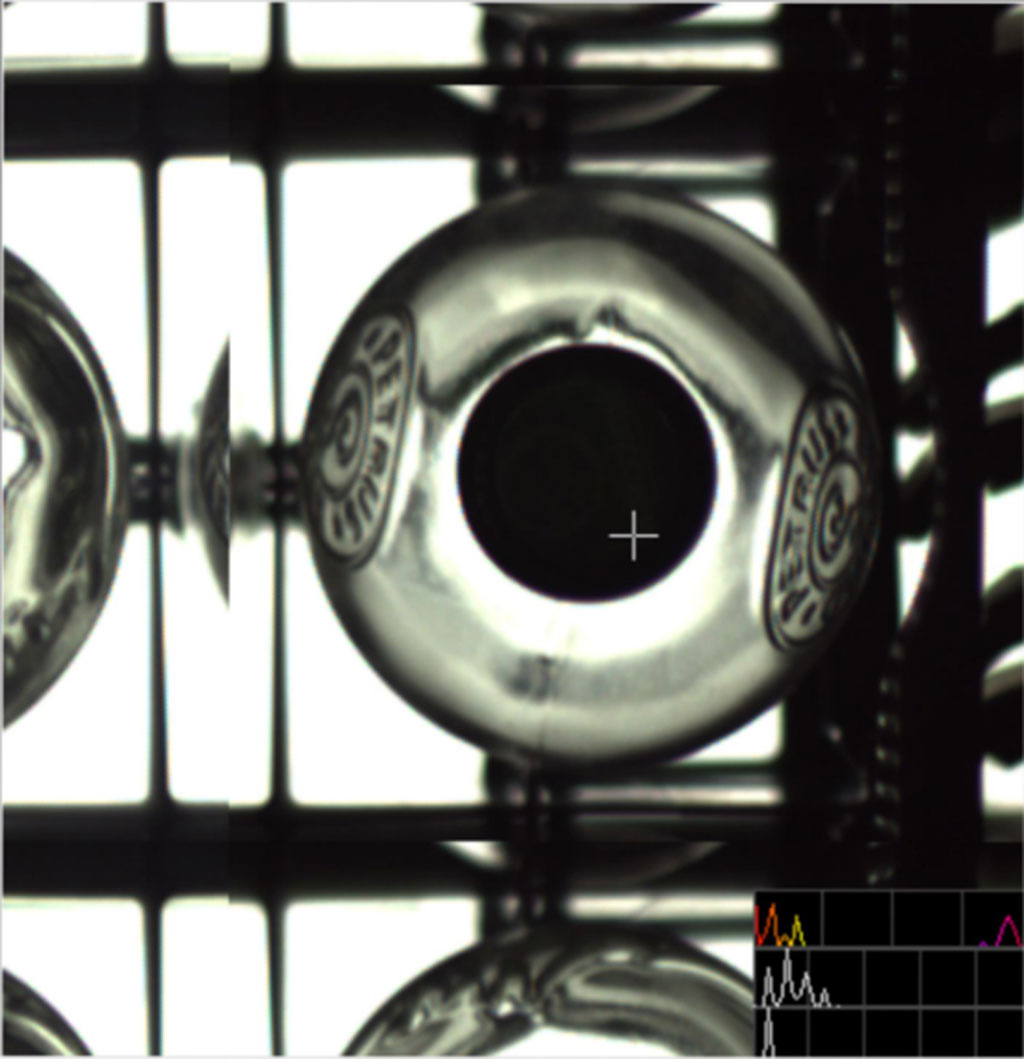

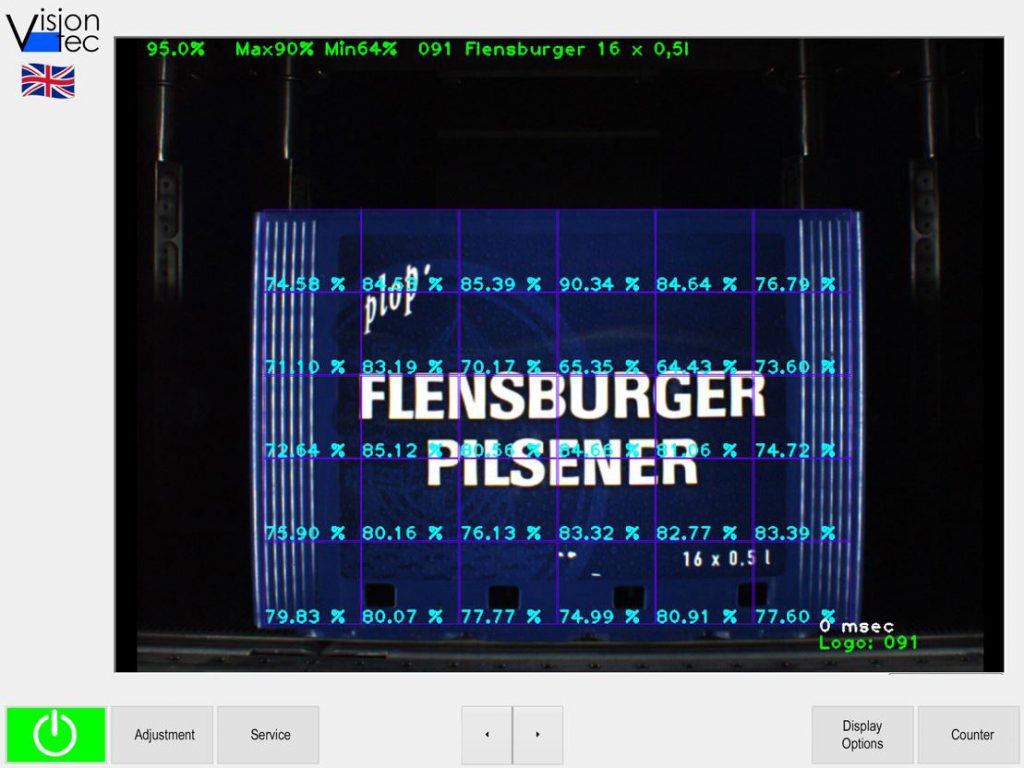

Logo inspections

The crate logo is inspected on one to four sides with one (or more) laterally arranged camera systems. Both a pure logo identification and a logo quality check are possible, during which the following inspection criteria are checked:

- logo shape

- logo color

- contaminants

- damages

- labels/stickers

- OCR reading

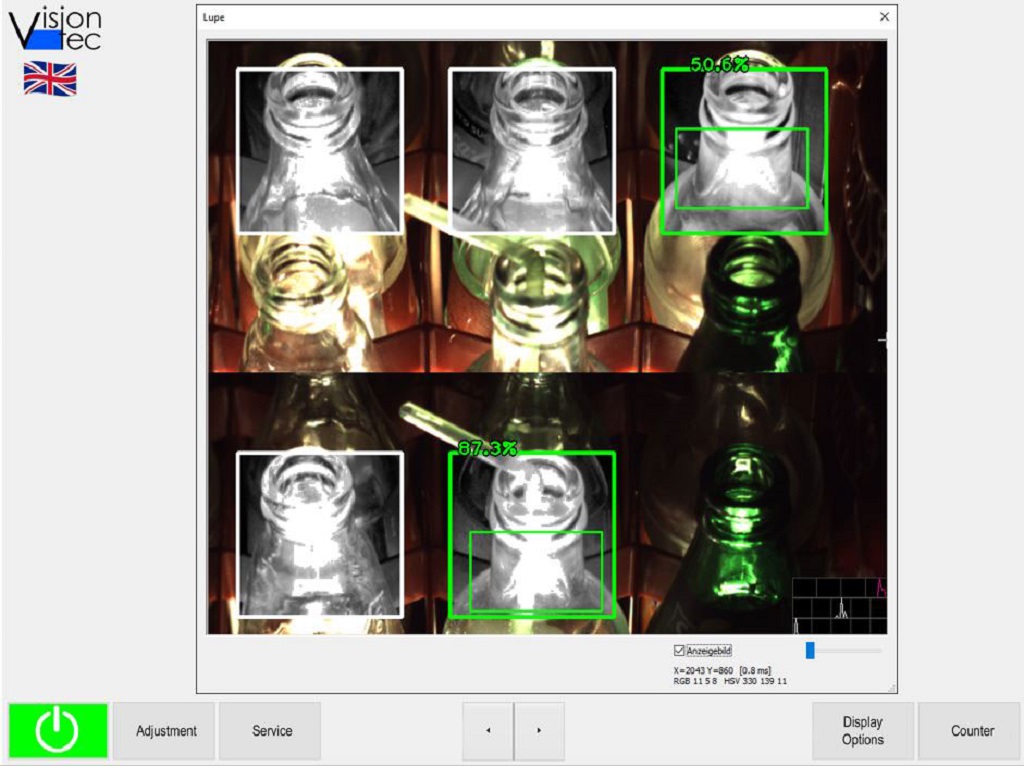

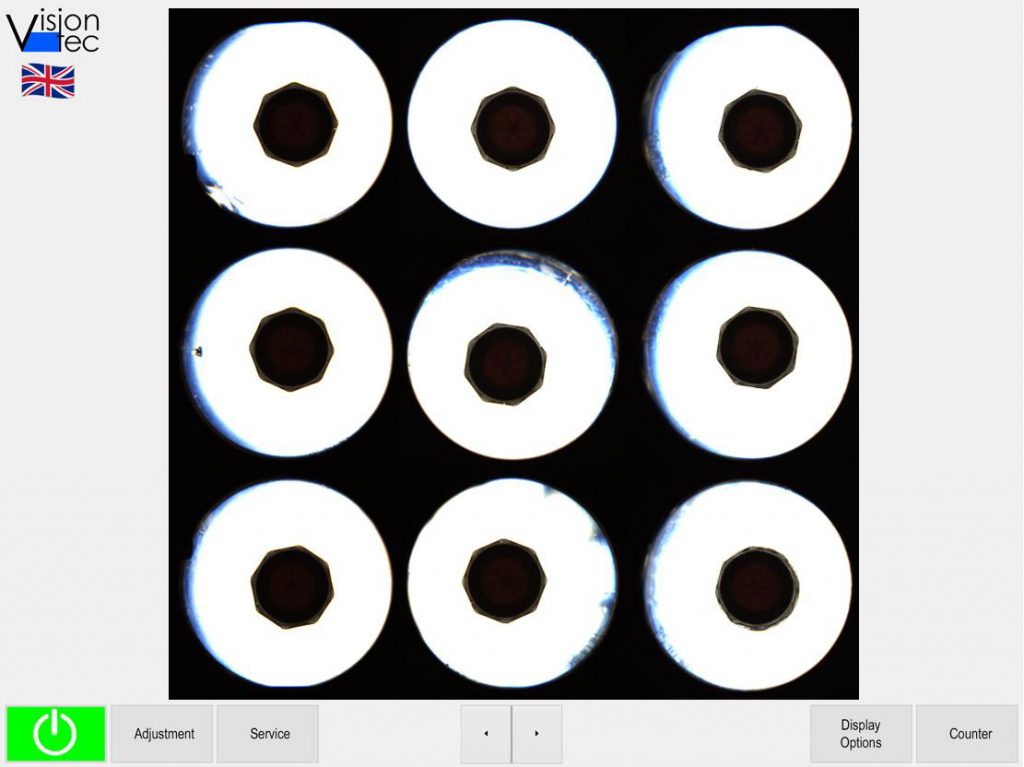

Empty crate inspection

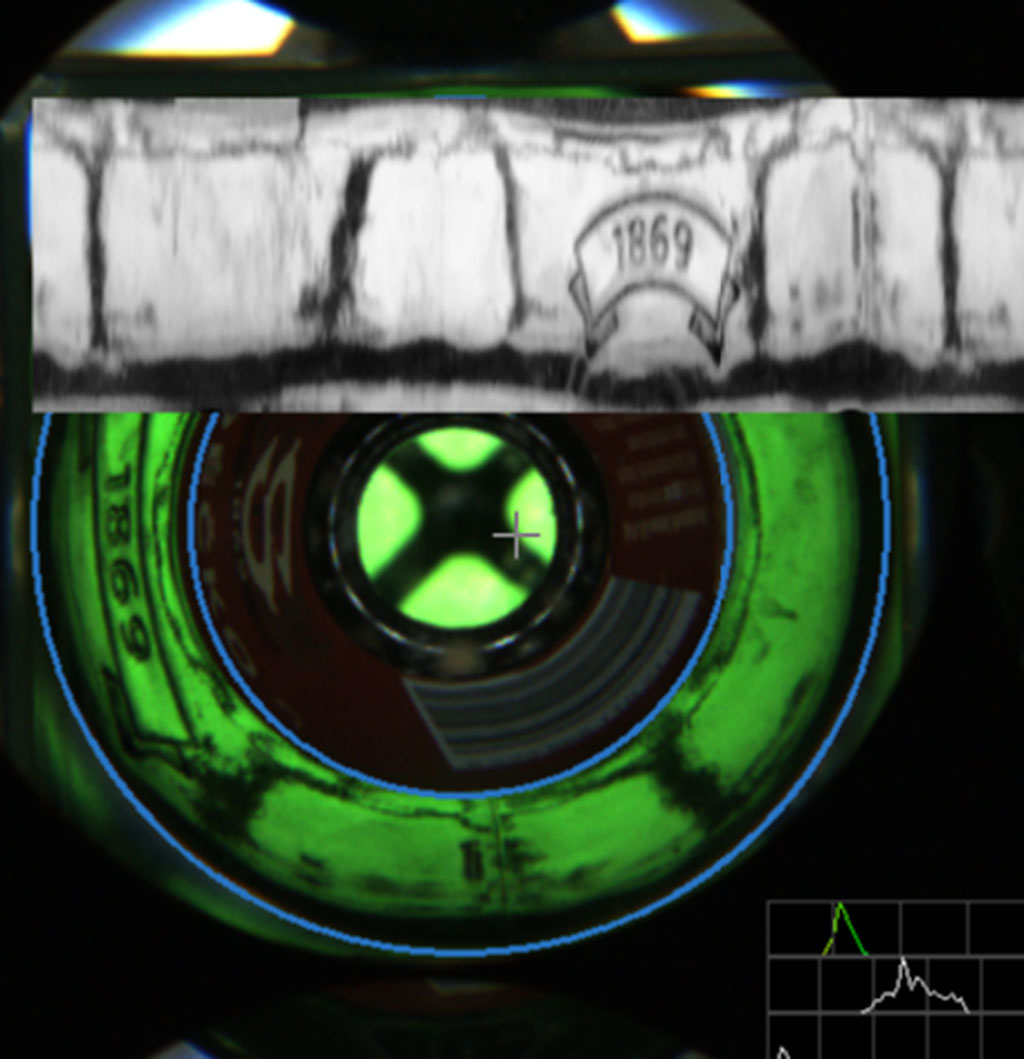

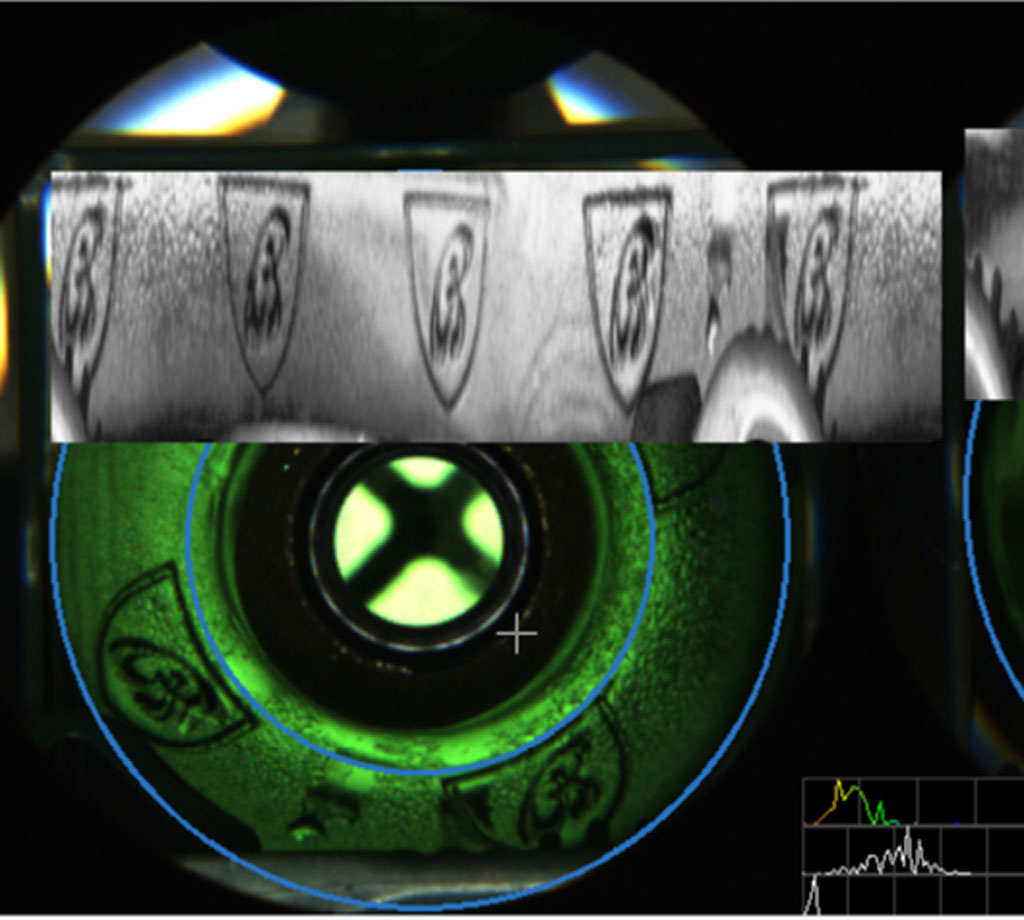

In empty crate inspection using a camera, a vertical camera system captures a bright and high-contrast image of the partition floor – regardless of the crate colour – using a special image capture process. Lighting from below is not required.

Inspection criteria:

- Foreign objects or residual bottles/bottle bottoms in the crate

- Crate geometry

- Deformation of the handle strips – as far as visible from above

- Cut-outs in the handle strips (> 15 mm) – as far as visible from above

- Crate colour

- Completeness of the bottom partitions

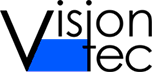

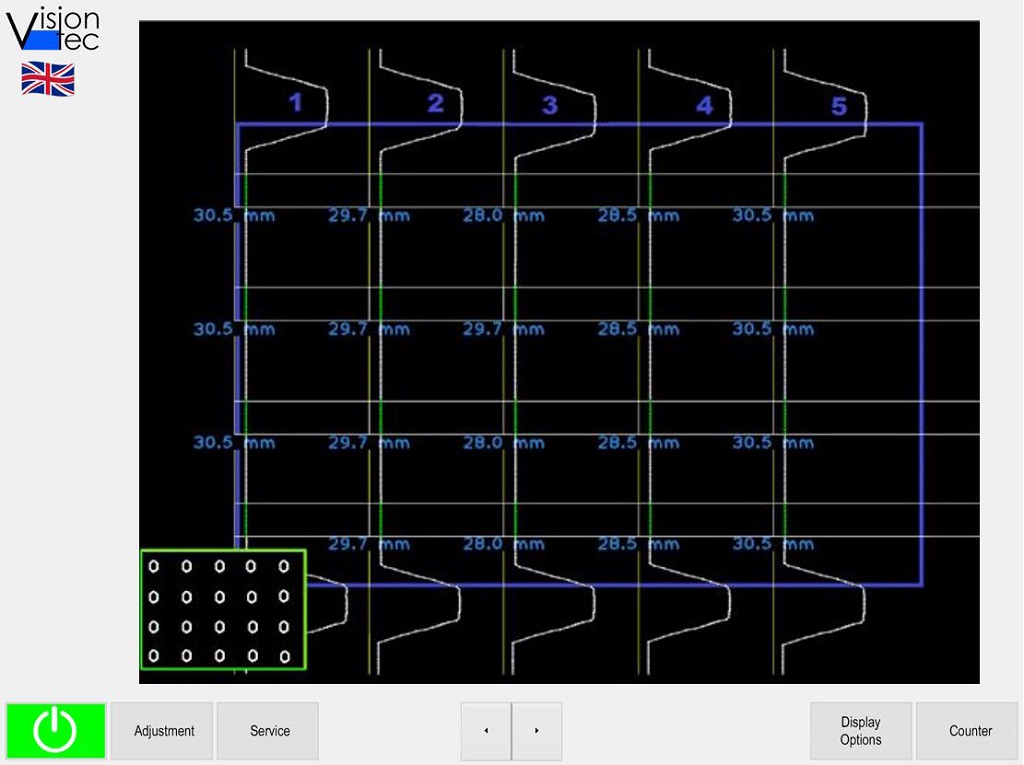

In empty crate inspection using ultrasonic sensors, an ultrasonic line is used to check whether a crate is empty or filled with bottles. An oscilloscope scan of each bottle row is displayed on the surface of each crate so that simple troubleshooting is supported in the event of malfunctions or changes to the conveyor system.

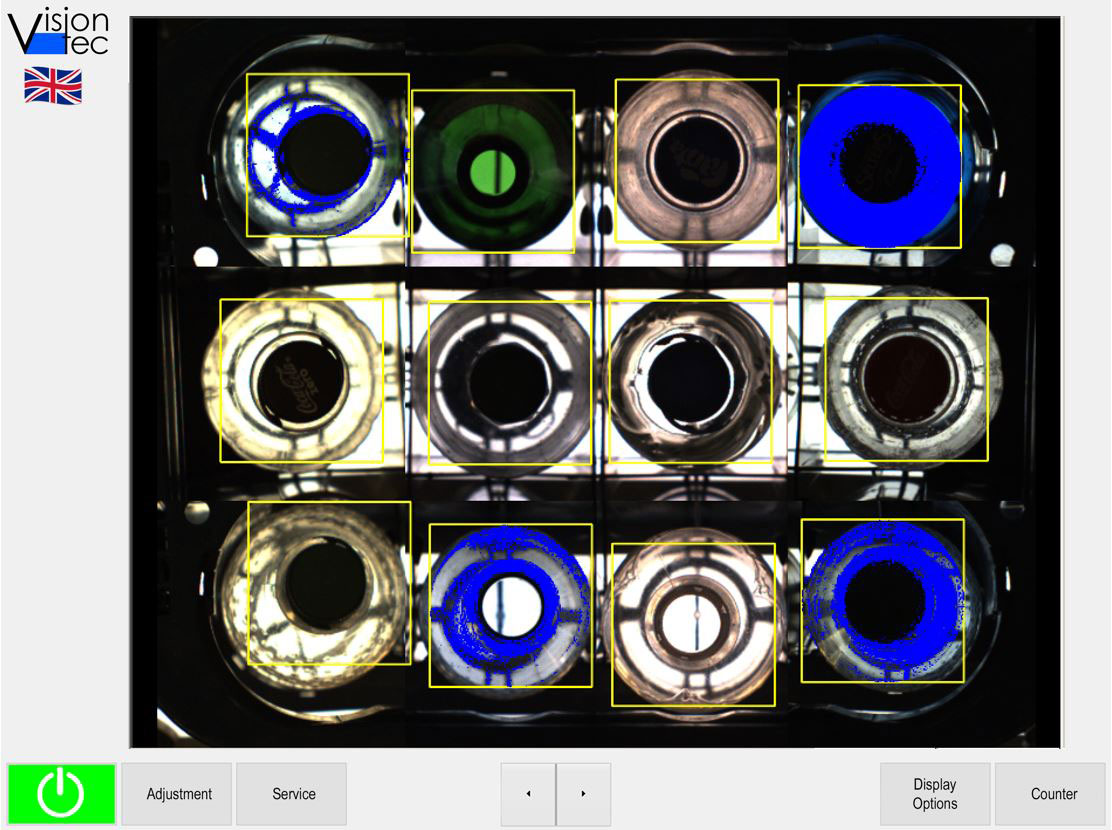

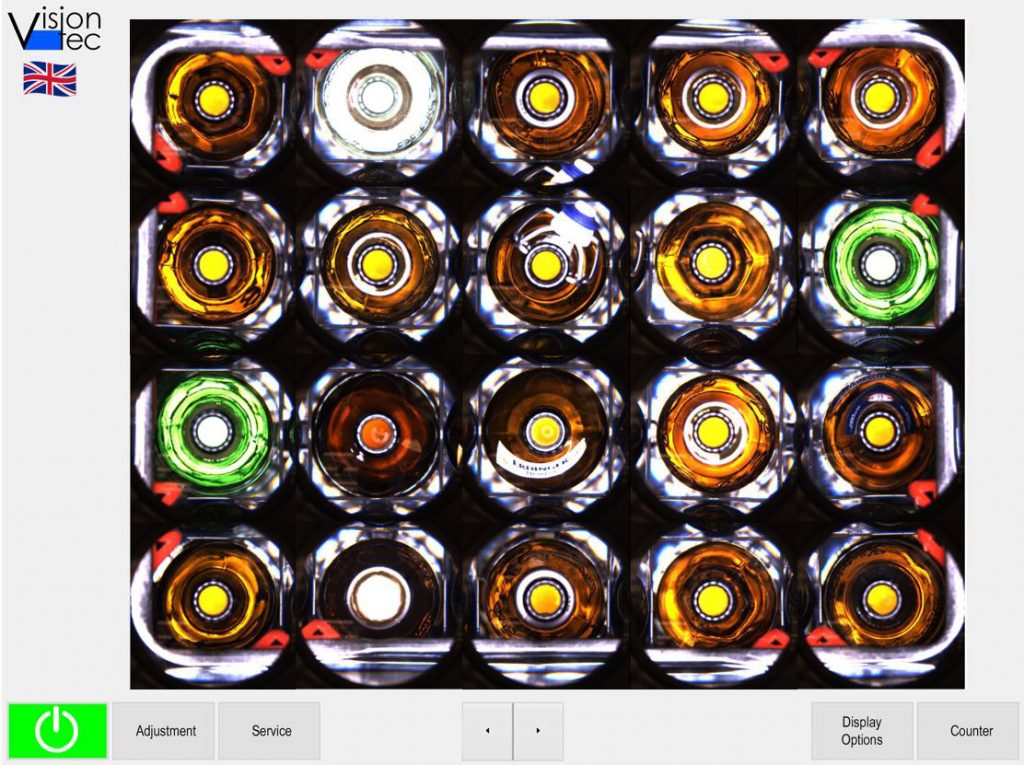

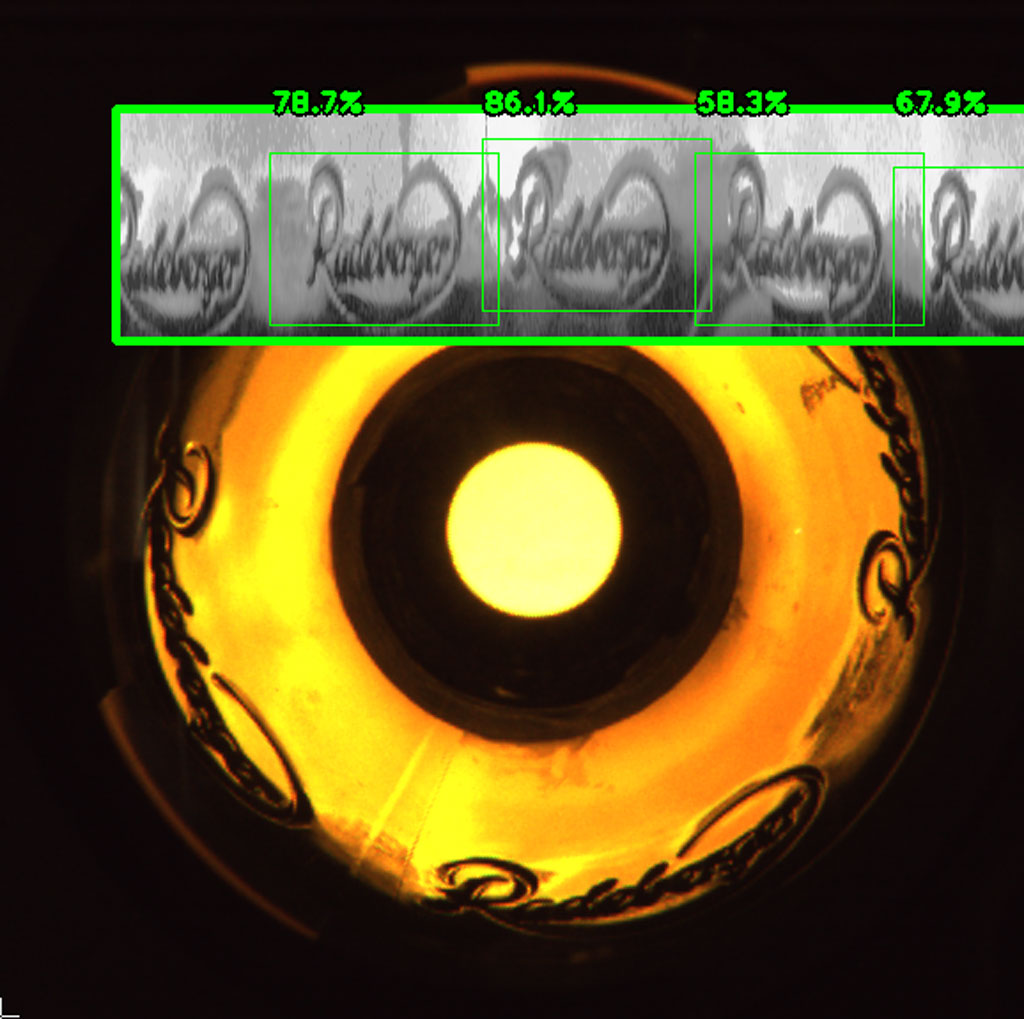

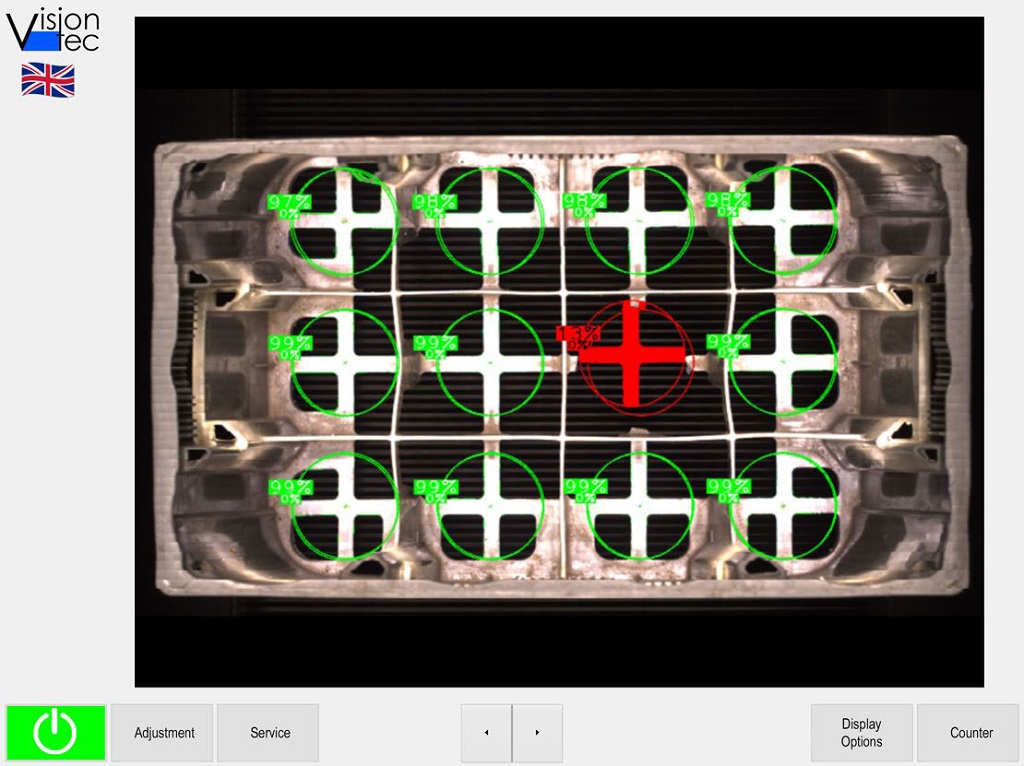

Full crate inspection

The full crate inspection is carried out – analogous to the empty crate inspection – either by means of a camera system or by means of an ultrasonic line, which scans the caps of the bottles and transmits the signals to the evaluation unit.

Depending on the task, an additional camera system can also be used for camera inspection, doubling the resolution and allowing the caps to be checked for the correct logo.